Smart Tips About Is An Inverter A Motor Controller

Frequency Inverter Motor Controller Guangzhou China VFD And

Inverters and Motor Control

1. What's the Buzz About Inverters and Motors?

Ever wondered what makes that electric car zoom or how the speed of a conveyor belt in a factory is so precisely managed? The answer often involves sophisticated electronics controlling electric motors. Two key players in this field are inverters and motor controllers. But are they the same thing? Are they just different terms for the same gadget? Let's dive in and unravel this electrical enigma.

Think of an electric motor like a powerful, but somewhat stubborn, workhorse. It needs the right kind of "fuel" (electrical energy) to run efficiently and at the desired speed. Thats where the clever electronics come in. Both inverters and motor controllers play roles in providing and shaping this "fuel."

To put it simply, they are related but not identical. An inverter can be a crucial component within a motor controller, but a motor controller is generally a more comprehensive system with additional functionalities.

Consider this analogy: An inverter is like the carburetor in an old car—it takes the raw "fuel" (DC electricity) and prepares it for the engine (motor). A motor controller, on the other hand, is the entire engine management system—it handles fuel, ignition timing, and all the other parameters to keep the engine running smoothly.

Speed Control Of 3ph Induction Motor Using VVVF Drive

Decoding the Inverter

2. The Magic of Conversion

The primary job of an inverter is to convert Direct Current (DC) electricity into Alternating Current (AC) electricity. This is crucial because most electric motors are designed to run on AC power. DC power, commonly found in batteries (like in electric vehicles or solar panels), isn't directly usable for these motors.

Imagine a simple circuit with a battery powering a light bulb. Thats DC power in action. Now, picture that same battery powering a much larger motor. The motor likely needs AC. The inverter acts as the middleman, efficiently switching the DC on and off in a specific pattern to simulate AC.

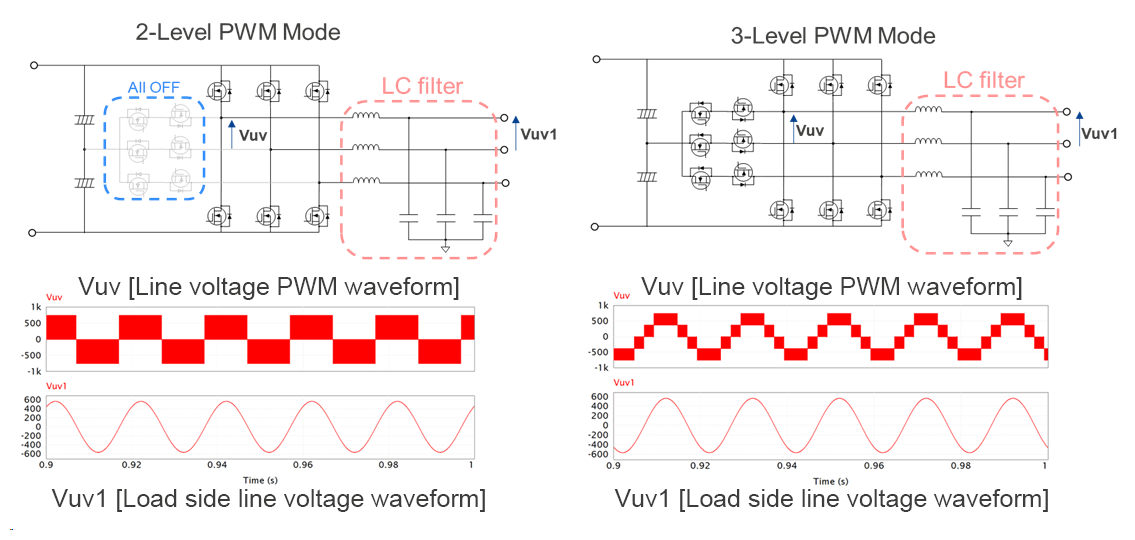

The clever part is that by controlling the frequency of this switching, the inverter can control the frequency of the generated AC. And, as many seasoned engineers know, motor speed is directly related to the frequency of the supplied AC power. So, essentially, an inverter gives you basic speed control, at least in principle.

Inverters also play a crucial role in renewable energy systems. Solar panels and batteries store energy as DC. For this energy to be used in household appliances (which run on AC), it must be converted by an inverter.

What Exactly Is a Motor Controller?

3. More Than Just Speed

A motor controller is a more complex device. While it might include an inverter (for AC motor control), it also incorporates a range of other features designed to precisely manage the motor's operation. Think of it as the brain and nervous system of the motor system.

These features can include things like: current limiting (to protect the motor from overloads), voltage control (to ensure the motor receives the correct voltage), braking control (to stop the motor quickly and safely), and feedback mechanisms (to monitor the motor's performance and adjust settings accordingly). Modern motor controllers also often have sophisticated protection circuits and communication capabilities.

Motor controllers often have sophisticated algorithms and logic to optimize motor performance and efficiency. They can adapt to changing load conditions, preventing the motor from stalling or overheating. Advanced models often incorporate features like sensorless vector control or field-oriented control, enabling precise torque and speed regulation.

Consider industrial automation, where robots need precise and controlled movements. The motor controllers ensure that the motors driving these robots perform exactly as required, smoothly and reliably. In this case, an inverter by itself simply wouldn't cut it.

When Do You Need What? The Application Matters

4. Matching the Tool to the Task

The choice between an inverter and a full-fledged motor controller depends heavily on the specific application and the level of control you need. A simple application might only need a basic inverter, while others will require a motor controller.

If you are working on a small project that requires simple on/off functionality, or a limited control, the inverter is a good decision. However, If you need to control other aspects of the motor, like a conveyor belt, a motor controller is the way to go.

Think about a simple ceiling fan. It usually has a basic speed control switch. The motor driving it might only require a very basic inverter, perhaps even integrated directly into the motor itself. Compare this to a high-speed CNC milling machine, where the spindle motor's speed and torque need to be precisely controlled for optimal cutting performance. Here, a sophisticated motor controller is essential.

So, the key takeaway is to analyze the requirements of your specific application. What level of control do you need? What protection features are necessary? Understanding these needs will guide you towards the appropriate solution.

Wiring Diagrams For Motor Control Circuits

Inverter as part of Motor Controller

5. Understanding the Relationship

It's really important to understand that an inverter, in the context of motor control, is most frequently seen as a part of a more extensive motor control system. It rarely operates entirely in isolation in demanding industrial applications.

Think of a fancy coffee machine. It has lots of components: a water heater, a pump, various sensors, and a control panel. The water heater is essential, but it's not the whole machine. Similarly, the inverter is crucial for converting DC to AC for the motor, but it's just one piece of the bigger puzzle.

Motor controllers leverage the inverter's DC-to-AC conversion capability but add layers of sophistication. This sophistication allows for features like regenerative braking, precise torque control at varying speeds, and sophisticated fault diagnostics, all controlled by advanced microprocessors and algorithms.

So, while the inverter is a vital component, remember that the motor controller is the mastermind orchestrating the motor's performance in a coordinated and optimized fashion.

How Does An Inverter Control The Speed Of A Motor At Justin Randy Blog

FAQ

6. Q

A: In theory, yes, to some extent. But, for precise and reliable speed control, especially under varying loads, a proper motor controller is highly recommended. Standard inverters may not provide the necessary feedback and adjustments for optimal performance.

7. Q

A: Not at all! While they are prevalent in industrial settings, motor controllers are also used in smaller applications, such as electric vehicles, home appliances (like washing machines with variable-speed motors), and even in some drones for precise rotor control.

8. Q

A: It depends. Sometimes, yes, if the existing motor is compatible and the inverter has the necessary control interfaces. However, in most cases, it's best to replace the entire system with a properly matched motor controller for optimal performance and reliability.