Best Tips About What Causes Dielectric Loss

Figure S7 Dielectric Loss As A Function Of The Frequency At Regularly

Unraveling the Mystery of Dielectric Loss

1. The Invisible Energy Thief

Ever wondered where a little bit of energy disappears when you're dealing with electrical components? It's not always a gremlin stealing it, but often a phenomenon called dielectric loss. Think of it as the subtle tax your electrical materials pay when they're doing their job of storing energy. But what exactly causes this loss? That's the million-dollar question, isn't it? Well, maybe not a million dollars, but definitely worth understanding if you're tinkering with circuits or designing anything electrical!

Dielectric loss, at its core, is the energy dissipated as heat in a dielectric material (like the insulation in a capacitor or the material surrounding a cable) when subjected to an alternating electric field. Imagine the molecules inside that material jiggling around frantically, trying to keep up with the constantly changing field. All that molecular motion creates friction, and friction, as we all know, generates heat. And that heat? Yep, that's the lost energy we're talking about.

It's like trying to herd cats — only instead of cats, it's tiny, polarized molecules. The electric field is constantly changing its direction, and the molecules are trying to align themselves accordingly. This constant back-and-forth, this relentless "dance," generates internal friction and energy dissipation. Its not a perfect system, and nothing in the real world ever truly is!

The impact of dielectric loss isnt always immediately obvious, but it can add up over time. Consider a high-voltage power line. The dielectric material insulating the cable is constantly exposed to a strong alternating electric field. Over time, the cumulative dielectric loss can lead to significant heating, potentially degrading the insulation and reducing its lifespan. This means more frequent maintenance and replacement, not to mention potential safety hazards. So, understanding the underlying causes is pretty important!

The Usual Suspects

2. Deconstructing the Loss Mechanisms

Several factors play a role in causing dielectric loss. It's not just one single thing, but rather a combination of mechanisms working together. Think of it as a team of tiny energy bandits, each contributing to the overall heist. The main culprits are generally attributed to polarization mechanisms and conductivity.

First, let's talk about polarization. Dielectric materials contain molecules that can be polarized, meaning they develop a positive and negative end when exposed to an electric field. There are several types of polarization, each contributing to dielectric loss differently. One type is dipole polarization, where molecules with permanent dipoles (like water) try to align with the electric field. But because the field is alternating, they're constantly trying to reorient themselves, leading to friction and heat. Another is ionic polarization, where ions in the material are displaced by the electric field, causing vibrations and energy loss.

Another contributing factor is interfacial polarization, which occurs when charges accumulate at interfaces between different materials or phases within the dielectric. Imagine tiny pockets of trapped charges building up and then suddenly discharging as the electric field changes. This discharging process generates heat and contributes to dielectric loss. Think of it like tiny, localized short circuits occurring within the material.

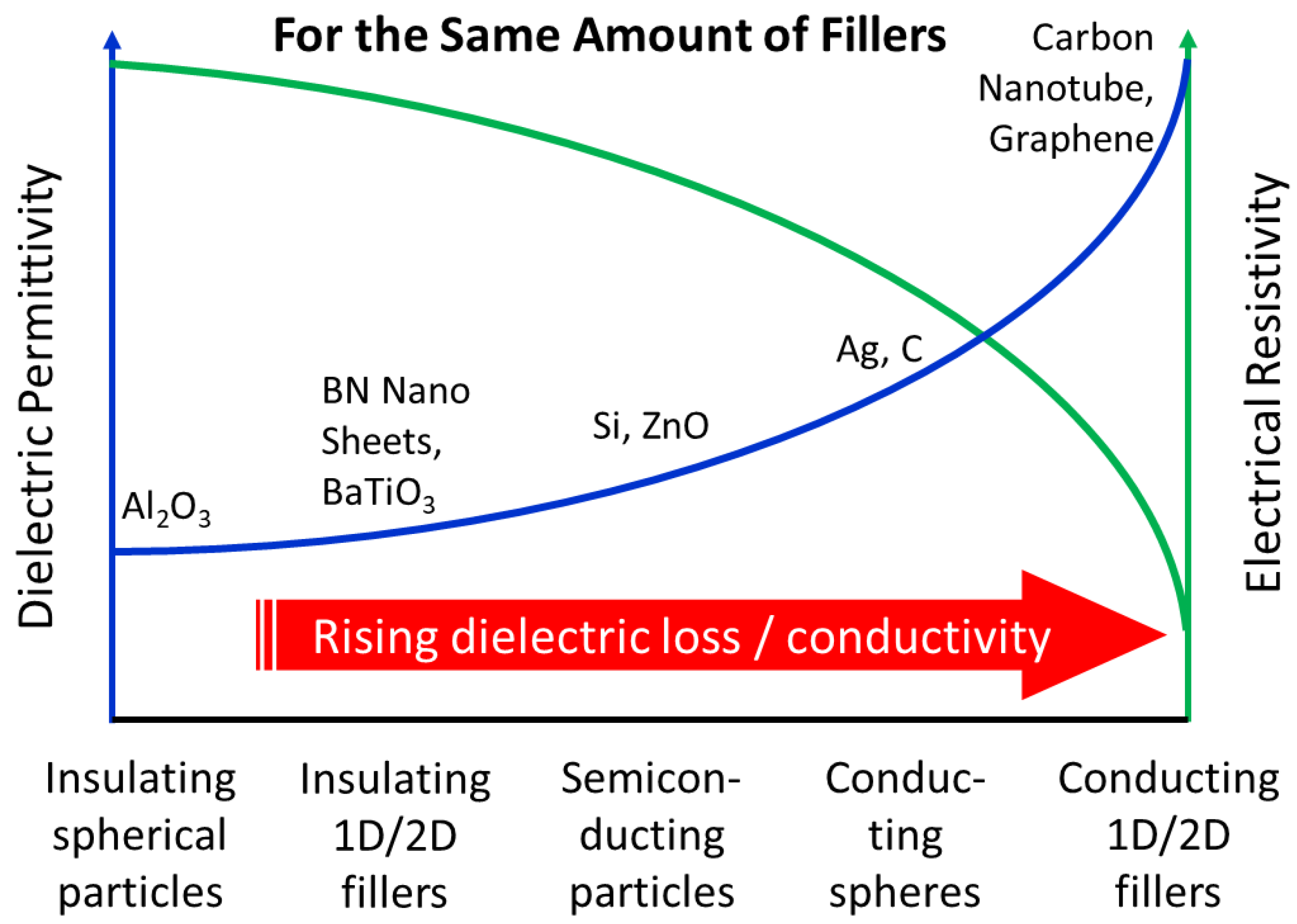

Lastly, the dielectric material's conductivity (how well it conducts electricity) plays a role. Even good insulators aren't perfect, and they have a small amount of conductivity. This conductivity allows a small current to flow through the material, and the resistance to this current generates heat, further contributing to dielectric loss. The higher the conductivity, the more energy is lost as heat. It's like trying to stop a leak in a dam — even a small leak can cause significant damage over time.

Dielectric Loss And Electrical Conductivity Behaviors Of Epoxy

Temperature's Role

3. The Thermal Connection

Temperature has a significant impact on dielectric loss. As the temperature of a dielectric material increases, the molecular motion within the material also increases. This increased molecular motion leads to more friction when the material is subjected to an alternating electric field, resulting in higher dielectric loss. It's like turning up the thermostat on those molecular "cats," making them even more hyperactive and difficult to control.

Higher temperatures also affect the conductivity of the dielectric material. In general, the conductivity of a material increases with temperature. This means that more current can flow through the material, leading to higher resistive losses and increased dielectric loss. Think of it as widening the pipe through which the energy leak is flowing, allowing more energy to escape.

Furthermore, temperature can affect the polarization mechanisms within the material. For example, at higher temperatures, the dipoles in the material may be more easily aligned with the electric field, leading to increased dipole polarization and higher dielectric loss. It's like greasing the gears of the molecular alignment machine, making it work even more efficiently at converting electrical energy into heat.

Therefore, it's crucial to consider the operating temperature of a dielectric material when designing electrical components. Selecting materials with lower dielectric loss at the expected operating temperature can significantly improve the efficiency and lifespan of the component. Its all about choosing the right tool for the job, and understanding how that tool behaves under different conditions.

Frequency Dependence Of A Dielectric Loss ε′, And B ε

Frequency's Influence

4. The Rhythm of Energy Loss

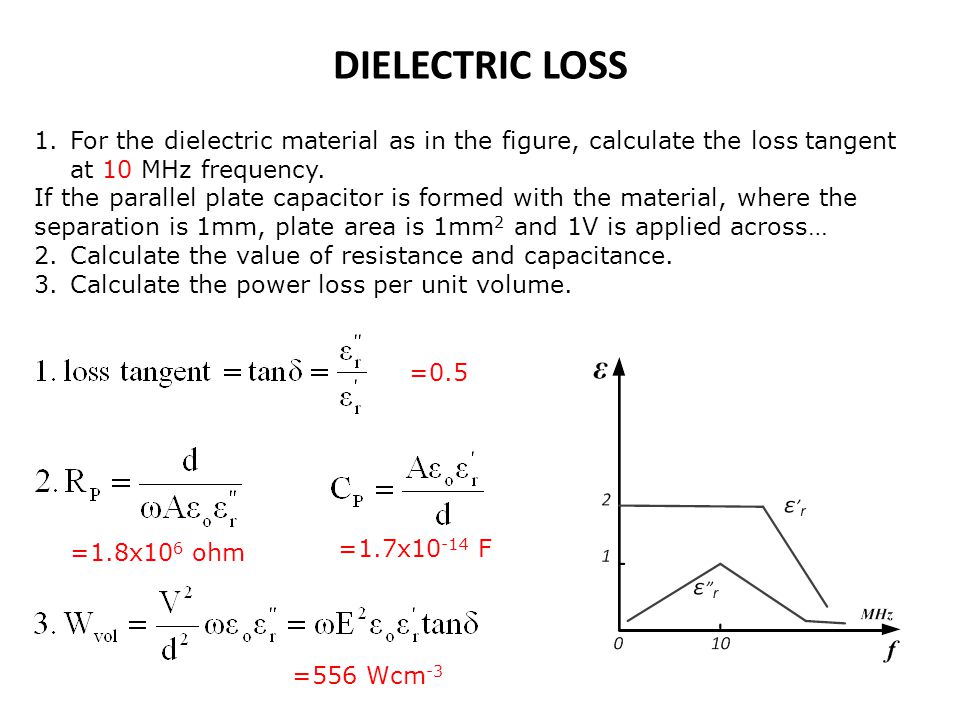

The frequency of the alternating electric field also plays a crucial role in dielectric loss. At low frequencies, the molecules in the dielectric material have enough time to fully align themselves with the electric field before it changes direction. In this case, the dielectric loss is relatively low because there is less molecular friction.

However, as the frequency increases, the molecules have less time to align themselves before the electric field changes direction. This leads to increased molecular friction and higher dielectric loss. Think of it as trying to force those molecular "cats" to dance to an increasingly fast and frantic beat. They're bound to stumble and create more chaos (and heat) in the process.

At very high frequencies, the molecules may not be able to keep up with the changing electric field at all. In this case, the dielectric loss may decrease slightly. However, other loss mechanisms, such as relaxation losses, may become more dominant at these frequencies. Relaxation losses occur when the molecules don't have enough time to fully relax back to their original state before the electric field changes again. This can also lead to energy dissipation.

Therefore, the frequency of the electric field is a critical factor to consider when selecting a dielectric material. Different materials have different dielectric loss characteristics at different frequencies. Choosing a material that has low dielectric loss at the operating frequency of the application can significantly improve the overall efficiency of the system. Finding the right frequency "sweet spot" can make a big difference in minimizing energy loss.

Material Matters

5. The Quest for Low-Loss Dielectrics

The type of dielectric material used has a huge impact on dielectric loss. Some materials have inherently lower dielectric loss than others due to their molecular structure and composition. For instance, polymers like polyethylene and polypropylene generally exhibit low dielectric loss at lower frequencies. These materials are often used in applications where minimizing energy loss is critical, such as in high-frequency cables and capacitors.

On the other hand, materials like water have a relatively high dielectric loss due to the presence of polar molecules that easily align with an electric field. This is why wet insulation can significantly increase dielectric loss and lead to electrical problems. Moisture is a common enemy of electrical insulation.

Ceramic materials, such as alumina and titania, can also exhibit varying levels of dielectric loss depending on their composition and manufacturing process. High-purity, well-processed ceramics tend to have lower dielectric loss than ceramics with impurities or defects. Choosing the right ceramic material is crucial in high-frequency applications like microwave components.

So, when selecting a dielectric material, it's essential to consider its dielectric loss characteristics at the operating frequency and temperature of the application. Consulting material datasheets and performing dielectric loss measurements can help engineers choose the best material for their specific needs. Its all about understanding the strengths and weaknesses of each material and matching them to the requirements of the application. Its kind of like dating finding the right match makes all the difference!

Introduction To Dielectric Loss In Transmission Lines Technical Articles

FAQs

6. Your Burning Questions Answered

Let's tackle some of the common questions about dielectric loss.

7. Why is dielectric loss important to consider?

Dielectric loss leads to energy waste in the form of heat. This can reduce the efficiency of electrical components and systems. It can also lead to overheating and premature failure of insulation, posing safety risks and increasing maintenance costs. It's a hidden cost that can add up over time.

8. How can dielectric loss be minimized?

Dielectric loss can be minimized by selecting dielectric materials with low loss tangents, operating at lower frequencies when possible, keeping temperatures low, and ensuring the material is dry and free from impurities. Its all about making smart choices in design and material selection.

9. What are some examples of applications where low dielectric loss is critical?

Low dielectric loss is critical in high-frequency circuits, high-voltage power transmission lines, capacitors, and insulation materials used in electronic devices. Any application where energy efficiency and reliability are paramount benefits from minimizing dielectric loss.