Recommendation Tips About How To Put Wire Into Connector

Connecting Wires

1. Why Connectors Matter (and a Little About Why I Once Short-Circuited My Christmas Lights)

Ever wondered how electricians manage to create organized, reliable circuits? It often boils down to using the right connectors. Let's face it, twisting wires together and hoping for the best just isn't a sustainable or safe solution. I learned that the hard way one Christmas when my poorly connected lights decided to give up on festive cheer halfway through decorating the tree. Sparks weren't exactly the holiday spirit I was going for!

Connectors come in all shapes and sizes, each designed for specific wire gauges, voltages, and environments. They create a secure, low-resistance connection that protects against shorts, loose connections, and potential hazards. Think of them as the unsung heroes of electrical work. They might not be glamorous, but they definitely keep things running smoothly (and safely!). Whether you're tackling a small DIY project or a more complex electrical task, understanding how to use connectors correctly is essential.

This guide will walk you through the basics of using different types of connectors. We'll cover everything from selecting the right connector for your project to the actual process of inserting the wire. Get ready to ditch the electrical tape (for all but the most basic insulation needs!) and embrace the world of secure, reliable connections.

And remember, when in doubt, always consult a qualified electrician. Electrical work can be dangerous if not done properly, and it's always better to be safe than sorry. So, let's dive in and shed some light on the world of wire connectors, shall we?

Choosing the Right Connector for the Job

2. Connector Types 101

Okay, so you're ready to connect some wires, but you're staring at a bewildering array of connectors. Don't panic! Let's break down some of the most common types you'll encounter. First up, we have wire nuts (also known as twist-on connectors). These are those little plastic caps you twist onto the end of joined wires. They're great for general-purpose connections in dry locations, like lighting fixtures or outlets.

Then there are push-in connectors, which, as the name suggests, allow you to simply push the wire into the connector. These are incredibly convenient and make for quick and easy connections. However, they're typically only suitable for solid-core wire and might not be the best choice for stranded wire or high-vibration environments.

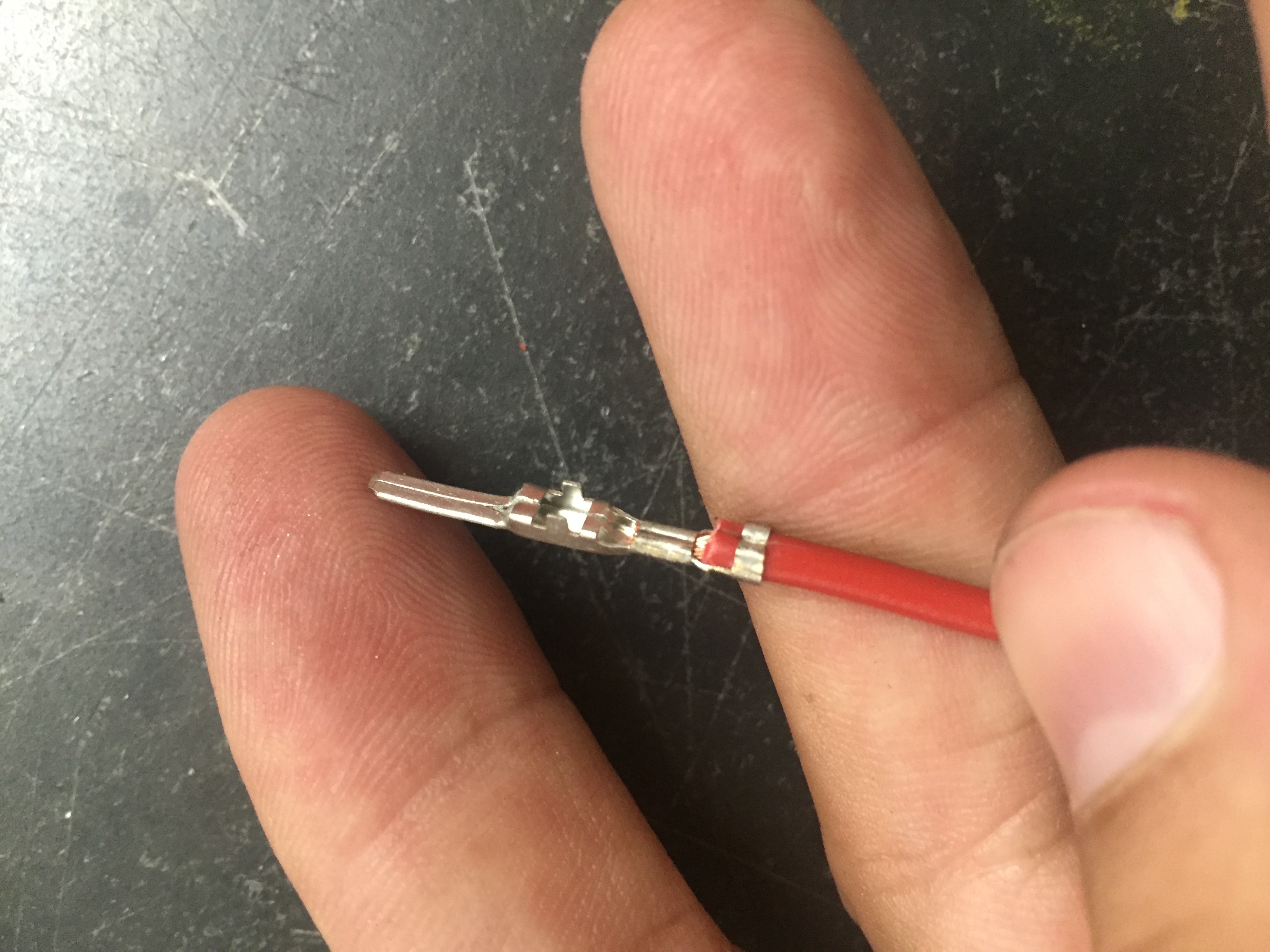

Another popular option is crimp connectors. These connectors use a crimping tool to create a tight, permanent bond between the wire and the connector. They're often used for automotive applications, speaker wires, and other situations where a reliable, vibration-resistant connection is needed. Finally, there are terminal blocks, which are essentially rows of screw-down terminals that allow you to connect multiple wires together neatly and organized.

Choosing the right connector depends on a number of factors, including the wire gauge, the voltage and amperage of the circuit, the environment (dry vs. damp), and the type of wire (solid vs. stranded). Always check the connector's specifications to ensure it's compatible with your application. Using the wrong connector can lead to loose connections, overheating, and even fire hazards. Remember, a little research goes a long way in ensuring a safe and reliable connection.

24 Ga Wire Connectors

Step-by-Step Guide

3. Wire Nuts, Push-in Connectors, and Crimp Connectors

Alright, time to get hands-on! Let's walk through the process of inserting wire into some of the most common types of connectors. First up, wire nuts. Start by stripping about 3/4 inch of insulation from the end of each wire you want to connect. Then, twist the wires together clockwise using pliers. Make sure the twisted portion is tight and secure. Finally, twist the wire nut onto the twisted wires, again in a clockwise direction, until it's snug. Give it a gentle tug to make sure the connection is solid. If the wires come loose, start over and twist them tighter this time.

Next, let's tackle push-in connectors. These are even easier! Simply strip about 1/2 inch of insulation from the end of the wire and push it firmly into the connector's designated hole. You should hear a click, indicating that the wire is locked in place. To remove the wire, use a small screwdriver or release tool to depress the release mechanism on the connector. Easy peasy!

Finally, let's try crimp connectors. First, strip about 1/4 inch of insulation from the end of the wire. Insert the stripped wire into the crimp connector, making sure it's fully seated. Then, use a crimping tool to crimp the connector onto the wire. Apply firm, even pressure with the crimping tool to create a tight, permanent bond. Give the wire a gentle tug to test the connection. If it comes loose, try crimping it again or using a different crimp connector. A good crimp should be strong and secure.

Remember, always double-check your connections to make sure they're solid and secure. A loose connection can cause all sorts of problems down the road. And when in doubt, don't hesitate to consult a qualified electrician. They can provide valuable guidance and ensure your connections are safe and reliable.

How To Wire Up Plugs The EASY WAY! (Cat5e / Cat6 RJ45 Pass

Troubleshooting Common Connection Issues

4. From Loose Wires to Overheating

Even with the best techniques, sometimes things go wrong. Let's talk about some common issues you might encounter when working with wire connectors. One of the most frequent problems is loose connections. This can happen if the wires aren't twisted tightly enough in wire nuts, if the push-in connector isn't fully engaged, or if the crimp isn't secure. Loose connections can lead to flickering lights, intermittent power, and even overheating, so it's important to address them promptly.

Another issue is overheating. This can be caused by a loose connection, an overloaded circuit, or using the wrong type of connector for the application. If you notice that a connector is hot to the touch or that the wires are discolored, disconnect the circuit immediately and investigate the cause. Overheating can be a serious fire hazard, so don't ignore it.

Sometimes, you might encounter problems with wire stripping. If you strip too much insulation, you'll expose too much bare wire, which can increase the risk of shorts. If you strip too little insulation, the connector might not be able to make a good connection. The key is to strip just the right amount of insulation — about 1/2 to 3/4 inch for most connectors.

If you're experiencing any of these issues, start by inspecting the connections. Make sure the wires are securely fastened, that the connectors are in good condition, and that there are no signs of damage or overheating. If you can't identify the problem, it's always best to consult a qualified electrician. They have the expertise and equipment to diagnose and fix electrical problems safely and effectively.

Automotive Wiring Splice Connectors

Safety First

5. Protect Yourself

Before you even think about touching a wire, let's talk safety. Electricity can be dangerous, so it's crucial to take precautions to protect yourself from shocks and hazards. First and foremost, always disconnect the power to the circuit you're working on. Flip the breaker switch off at the circuit breaker panel or remove the fuse. Use a voltage tester to confirm that the circuit is dead before you start working.

Wear appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses. This will help protect you from electric shocks and flying debris. Avoid working in damp or wet conditions, as water can conduct electricity and increase the risk of shock. Keep your work area clean and organized to prevent accidents.

Never work on electrical wiring if you're feeling tired or distracted. Electrical work requires focus and attention to detail. If you're not feeling up to the task, it's better to wait until you're fresh and alert. And remember, if you're not comfortable working with electrical wiring, don't hesitate to call a qualified electrician. They have the training and experience to handle electrical work safely and efficiently.

Finally, always follow local electrical codes and regulations. These codes are designed to ensure the safety of electrical installations and protect against fire and other hazards. Familiarize yourself with the codes in your area and make sure your work complies with them. By following these safety precautions, you can minimize the risk of accidents and ensure a safe and successful electrical project. Remember, your safety is paramount!

How To Connect Wires With Wire Connectors

FAQ

6. Your Burning Questions Answered

Still got questions? Here are a few common queries about wire connectors:

Q: Can I reuse wire nuts?

A: It's generally not recommended. Wire nuts are designed for a single use. Reusing them can compromise the connection and lead to problems. It's always best to use new wire nuts for each connection.

Q: What's the difference between solid and stranded wire connectors?

A: Solid wire connectors are designed for use with solid-core wire, while stranded wire connectors are designed for use with stranded wire. Using the wrong type of connector can result in a poor connection. Check the connector's specifications to ensure it's compatible with the type of wire you're using.

Q: How do I know what size wire nut to use?

A: Wire nuts are color-coded to indicate their size and the number and gauge of wires they can accommodate. Consult the wire nut's packaging or manufacturer's website for specific information on its capacity. Using the wrong size wire nut can result in a loose connection or damage to the wires.

Q: What should I do if a wire keeps slipping out of a push-in connector?

A: First, make sure you've stripped the correct amount of insulation from the wire (usually around 1/2 inch). If the wire still slips out, the connector might be damaged or worn out. Replace the connector with a new one.