Cool Info About What Frequency Is PWM

Understanding PWM Frequency

1. What Exactly Is PWM? (In Plain English, Of Course)

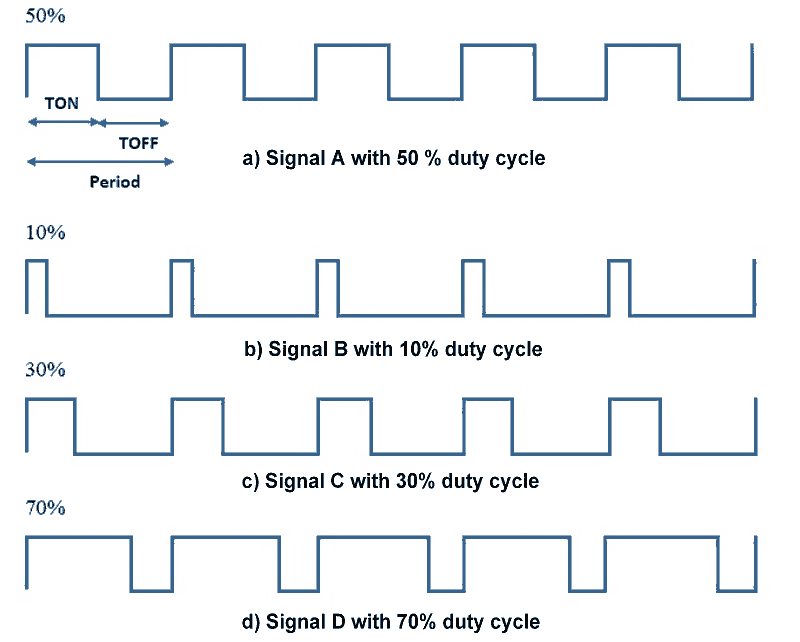

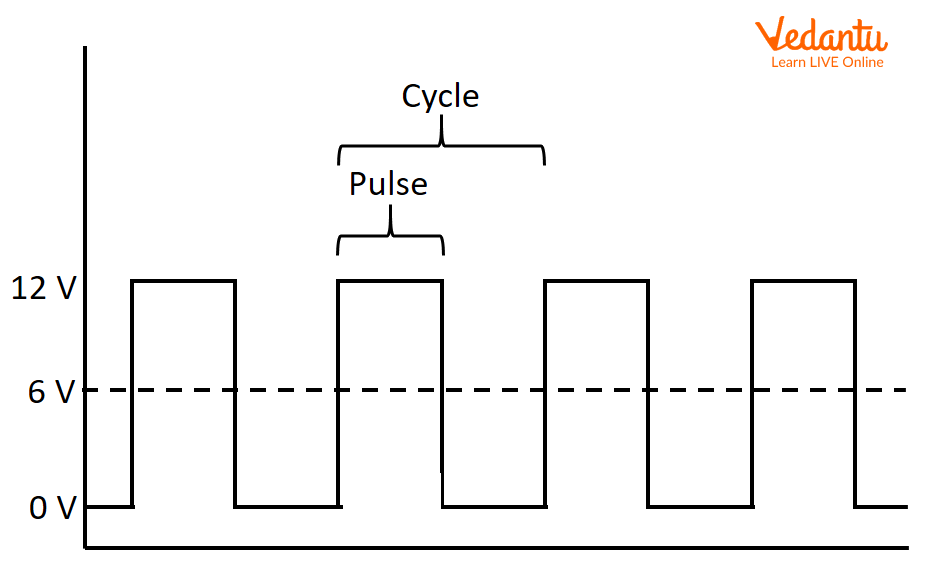

Let's cut through the jargon, shall we? PWM, or Pulse Width Modulation, is a clever technique used to control the power delivered to electrical devices. Think of it like a dimmer switch for a light bulb, but instead of physically adjusting a knob, it's all done electronically. The 'pulse' part refers to a series of on-off signals, and the 'width' refers to the duration of the 'on' part of each signal. By varying this width, we effectively change the average voltage supplied to the device.

Imagine a tiny switch flipping on and off incredibly fast. The longer the switch stays 'on' during each cycle, the more power the device receives. If it's 'on' half the time and 'off' half the time, the device gets roughly 50% of the maximum power. Pretty neat, huh?

This method is super efficient because the switch is either fully on or fully off, minimizing energy waste. This makes it ideal for controlling things like motor speed, LED brightness, and even heating elements. So, next time you see a smoothly dimming LED, you're likely witnessing the magic of PWM in action.

But what about that frequency thing? Well, that's where things get interesting...

2. Frequency

Okay, so we know PWM involves switching things on and off. The PWM frequency tells us how quickly this switching happens. It's measured in Hertz (Hz), which represents cycles per second. A higher frequency means the switch is flipping on and off more times each second.

Think of it like a strobe light. A slow strobe (low frequency) might flash only a few times per second, creating a noticeable flickering effect. A fast strobe (high frequency) flashes so rapidly that it appears as a continuous light. Similarly, with PWM, the frequency impacts how smoothly the controlled device behaves. A poorly chosen frequency can lead to undesirable effects like audible noise or jerky motor movements.

The choice of frequency is crucial and depends heavily on the application. For example, audio amplifiers often use very high PWM frequencies (hundreds of kHz) to ensure that any switching noise is far beyond the range of human hearing. On the other hand, controlling a large heating element might only require a relatively low frequency.

Essentially, you want the frequency high enough that the device responds smoothly and without unwanted artifacts, but not so high that it causes excessive switching losses or electromagnetic interference (EMI).

3. Why Does PWM Frequency Even Matter? (The Practical Side)

Alright, enough theory. Let's get practical. Why should you, the average human, care about PWM frequency? Well, depending on what you're building or tinkering with, it can make a significant difference in performance and overall user experience.

Consider controlling a DC motor, for instance. A low PWM frequency might cause the motor to vibrate or produce an annoying buzzing sound as the pulses turn it on and off. Increasing the frequency typically smooths out the motor's operation and reduces the noise. However, pushing the frequency too high can also be detrimental. The motor's internal inductance can start to resist the rapid changes in current, leading to inefficiencies and potential overheating.

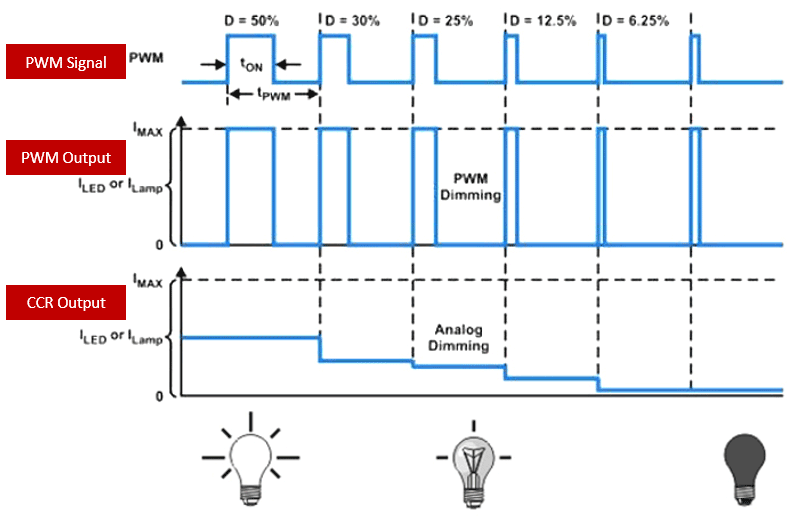

Similarly, when dimming LEDs, a low PWM frequency can result in visible flickering, which is particularly noticeable at lower brightness levels. This can be distracting and even cause eye strain. Increasing the frequency eliminates the flicker, creating a smooth, continuous dimming effect. But, as with motors, excessive frequencies can lead to increased power consumption and heat generation.

So, the sweet spot depends on the characteristics of the device being controlled. It's often a matter of experimentation and finding the optimal balance between smoothness, efficiency, and noise reduction. The datasheet for your motor, LED driver, or other device might suggest a recommended PWM frequency range.

4. Choosing the Right Frequency

Selecting the appropriate PWM frequency isn't an exact science. It often involves a bit of trial and error, coupled with a good understanding of the device you're controlling. There's a delicate balance to strike, and what works perfectly in one situation might be completely unsuitable in another.

Start by considering the load characteristics. Is it inductive (like a motor or inductor), capacitive (like a capacitor or LED driver), or resistive (like a heating element)? Inductive loads generally require lower frequencies to avoid excessive current spikes, while capacitive loads can often handle higher frequencies without issue. Resistive loads are typically less sensitive to frequency variations.

Next, think about the desired performance. Are you prioritizing smoothness, efficiency, or minimal noise? Higher frequencies generally lead to smoother operation but can also increase switching losses and electromagnetic interference. Lower frequencies can be more efficient but may result in audible noise or jerky movements.

Finally, consult the device's datasheet. Many manufacturers will specify a recommended PWM frequency range or provide guidelines for selecting an appropriate frequency based on the application. Don't be afraid to experiment and observe the device's behavior at different frequencies. A little tweaking can often yield significant improvements in performance and overall user satisfaction.

5. Frequently Asked Questions (The FAQ Section!)

6. Q

A: A too-low PWM frequency can lead to several undesirable effects. For motors, you might experience jerky movements, vibrations, or audible buzzing. For LEDs, you'll likely see visible flickering, especially at lower brightness levels. In some cases, it can even cause premature wear and tear on the device being controlled.

7. Q

A: Not quite. While PWM can theoretically operate at a wide range of frequencies, the practical range is limited by the capabilities of the controlling circuitry and the characteristics of the device being controlled. Extremely high frequencies can be difficult to generate and manage, while extremely low frequencies can result in poor performance.

8. Q

A: Nope! There's no one-size-fits-all answer. The optimal PWM frequency depends entirely on the specific application and the characteristics of the device being controlled. What works perfectly for dimming an LED might be completely unsuitable for controlling a motor. Experimentation and consultation with the device's datasheet are key to finding the sweet spot.

PWM Strategy (a) Sine And Triangular Waveform (b) S1/S4 Pulses (c

Pwm To Sine Wave

PWM (Pulse Width Modulation) Learn Important Terms And Concepts